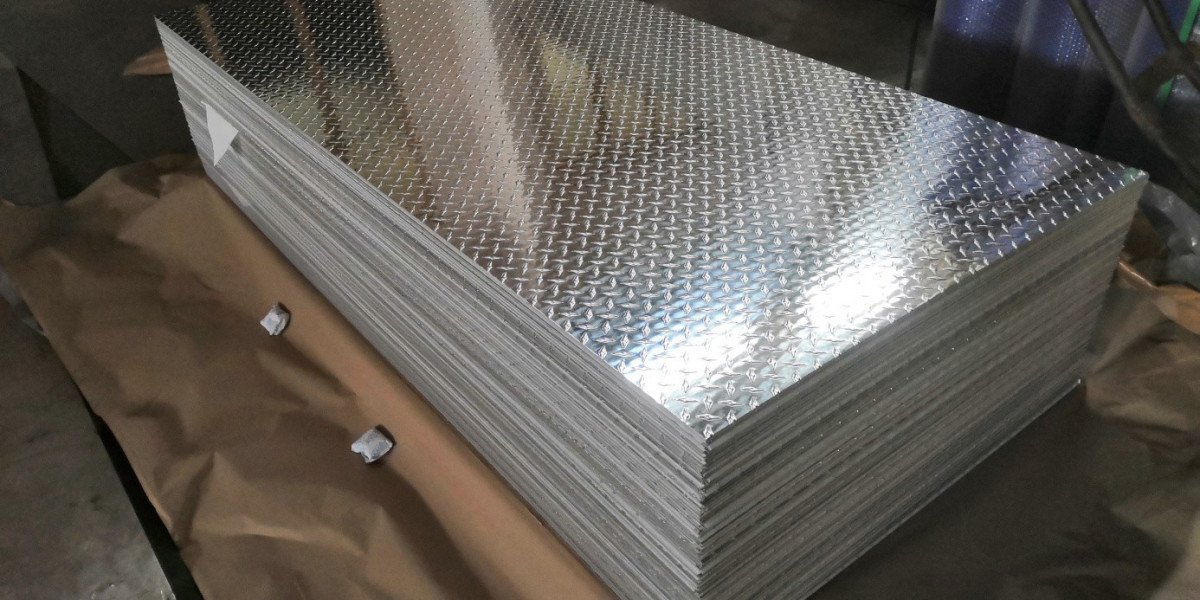

The 1060 and 3003 aluminum checker plate for trailers are adopted to the trailer panel to reap anti slid effect. The trailer panel adopts a 2-8mm thick aluminum diamond tread plate at the surface of the board to make your transportation safer. The friction coefficient will increase, and the friction adhesion is about 2 to three instances large than that of the overall flat aluminum plate. The design and manufacturing method of the aluminum checkered plate loading platform floor now not best reduces the load of the entire automobile, however also increases the lifting and loading capability, and also will increase the anti-skid function, that is lovely and realistic.

The aluminum checker plate for trailers has the characteristics of non-slip, anti-rust and anti-corrosion, long lasting and delightful in look. If the aluminum checkered plate is used for anti-slip impact, it's far necessary to deal with its basic pattern to growth the unevenness of its basic pattern, in order that the basic friction force for the aluminum checker plate can be elevated, and all sorts of anti-slip of the board are continuously finished, due to the fact the sample and surface of the checkered plate aluminum are to be executed to boom the roughness of its surface is the primary reason and the important thing factor of anti-slip.

The classification and characteristics of the aluminum checker plate for trailers:

1, regular plate:

Everyday plate usually refers to normal one thousand series aluminum checker plate. The general plate has low mechanical electricity (softer) and is easy to dent and deform, and has bad corrosion resistance and put on resistance. However, the general plate has exact welding performance and isn't always clean to crack. With a purpose to ensure that the trailer plate does now not seem critical concave deformation, the thickness of aluminum checker plate of trailer is usually 2.0 mm or greater.

2, Manganese plate:

Manganese plate is 3003 aluminum checker plate in 3000 collection Al-Mn-Mg alloy. The power, put on and corrosion resistance of 3003 aluminum checker plate is better than that of regular plate. The welding performance is much like that of regular plates. The thickness of the manganese plate bottom plate of the semi-trailer is generally above 1.8mm.

Procurar

Postagens Populares

-

Reignite the Flame: How to Bring Back Spontaneity and Passion in Sex with Your Husband

De JoeTyler

Reignite the Flame: How to Bring Back Spontaneity and Passion in Sex with Your Husband

De JoeTyler -

Sensual Shape

Sensual Shape

-

How To Find Escort Girls in Dubai

How To Find Escort Girls in Dubai

-

Escorts in Hong Kong - Exploring the Vibrant Adult Entertainment Scene

De Emilie Fahey

Escorts in Hong Kong - Exploring the Vibrant Adult Entertainment Scene

De Emilie Fahey -

Would You Like To Make Your Night Delightful With Call girls in Bahrain?

Would You Like To Make Your Night Delightful With Call girls in Bahrain?