Here's where downhole operation simulation comes in – a powerful tool for optimizing wellbore performance and maximizing production.

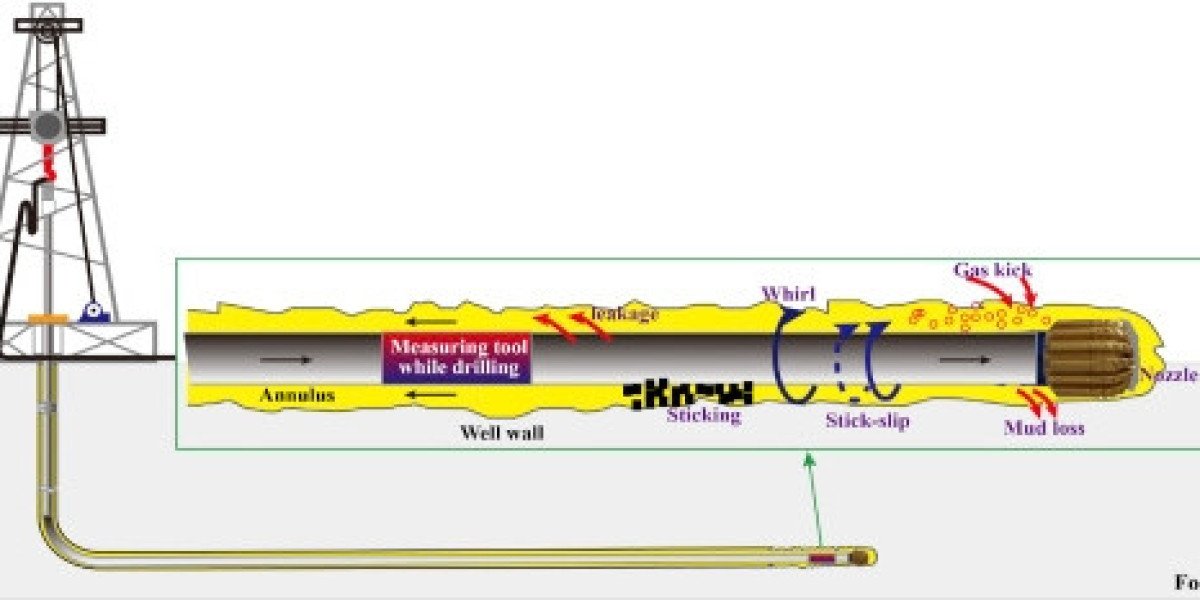

The Downhole Challenge

Downhole environments are complex and unforgiving. High pressure, extreme temperatures, and unpredictable formations all pose challenges during drilling and production. Traditional methods of wellbore design and operation often rely on experience and intuition, which can lead to inefficiencies and costly mistakes.

The Power of Downhole Simulation

Downhole operation simulation software utilizes advanced mathematical models to replicate the behavior of a wellbore under various conditions. This allows engineers to virtually test different drilling strategies, completion techniques, and production scenarios before ever setting foot on a rig.

Benefits of Downhole Simulation

Enhanced Wellbore Design: Simulate different wellbore trajectories and casing configurations to optimize wellbore stability and prevent costly collapses.

Improved Production Efficiency: Test various production scenarios to identify the most efficient methods for extracting hydrocarbons, maximizing yield.

Reduced Operational Risks: Identify potential problems like pressure surges or formation instability before they occur, allowing for proactive mitigation strategies.

Cost Savings: By optimizing drilling and production processes, downhole simulation can significantly reduce operational costs.

Environmental Benefits: By minimizing drilling risks and optimizing production efficiency, downhole simulation can contribute to a more environmentally friendly drilling operation.

A Look Inside the Simulation

Downhole simulation software considers various factors, including:

Reservoir properties: Rock permeability, porosity, and fluid saturation are all crucial for understanding reservoir behavior.

Drilling fluid properties: The type and properties of drilling fluids significantly impact wellbore stability and pressure control.

Completion techniques: Downhole equipment and techniques used to stimulate production are simulated to ensure optimal performance.

Production parameters: Flow rates, pressure, and temperature are all simulated to predict well performance and optimize production strategies.

The Future of Downhole Simulation

As technology advances, downhole simulation software is becoming even more sophisticated. Integration with real-time downhole data allows for continuous monitoring and adjustments during drilling and production, further optimizing wellbore performance.

Drilling for a Sustainable Future

Downhole operation simulation is a powerful tool that empowers oil and gas companies to drill smarter, not just harder. By optimizing wellbore performance, this technology can contribute to a more efficient, cost-effective, and sustainable drilling industry.