Chromium oxide (Cr2O3), a green-colored inorganic compound, is widely used in various industrial applications, including the production of pigments, refractories, ceramics, and as a catalyst in chemical reactions. The price of chromium oxide is influenced by multiple factors, such as raw material costs, production processes, demand and supply dynamics, and environmental regulations. This article provides an in-depth analysis of the factors affecting Chromium Oxide Price Chart, historical trends, and future outlooks.

Key Factors Influencing Chromium Oxide Prices

Raw Material Costs

- Chromite Ore: The primary raw material for chromium oxide production is chromite ore. The cost of chromite ore can fluctuate based on mining conditions, global supply and demand, and geopolitical factors. Major producers of chromite ore include South Africa, Kazakhstan, India, and Turkey.

- Energy Costs: The production of chromium oxide is energy-intensive, requiring significant amounts of electricity and heat. Fluctuations in energy prices, particularly electricity and natural gas, can impact production costs.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/chromium-oxide-price-trends/pricerequest

Production Processes

- Chemical Synthesis: Chromium oxide is typically produced through the reduction of sodium dichromate with sulfur. The efficiency and cost of this chemical process can influence the final price of chromium oxide.

- Alternative Methods: Other methods, such as the thermal decomposition of ammonium dichromate or the direct oxidation of chromium metal, can also produce chromium oxide. The choice of production method can affect costs based on the availability and price of raw materials and energy.

Market Demand

- Pigments: Chromium oxide is widely used as a green pigment in paints, coatings, plastics, and ceramics. Demand from these industries can significantly influence prices. Trends in the construction, automotive, and consumer goods sectors, which drive the demand for coatings and paints, directly impact the demand for chromium oxide pigments.

- Refractories and Ceramics: Chromium oxide is also used in the production of refractories and ceramics due to its high melting point and thermal stability. Demand from the steel, glass, and cement industries, which use refractory materials, affects the price of chromium oxide.

- Catalysts: Chromium oxide serves as a catalyst in various chemical reactions, including the production of synthetic rubbers and the processing of hydrocarbons. Industrial demand for catalysts can impact chromium oxide prices.

Supply Dynamics

- Global Production: The global production capacity of chromium oxide, including the number of manufacturing plants and their production efficiencies, influences supply levels and prices.

- Trade Policies: Import and export tariffs, trade agreements, and geopolitical tensions can affect the global supply chain of chromium oxide. Changes in trade policies in major producing or consuming countries can impact prices.

Environmental Regulations

- Emissions and Waste Management: The production of chromium oxide involves handling hazardous chemicals and emissions. Stringent environmental regulations can increase production costs due to the need for emissions control, waste management, and compliance with safety standards.

- Sustainability Initiatives: Increasing demand for environmentally friendly and sustainable products can influence the production processes and costs of chromium oxide. Companies may need to invest in greener technologies and practices to meet regulatory and consumer expectations.

Historical Price Trends

Price Volatility

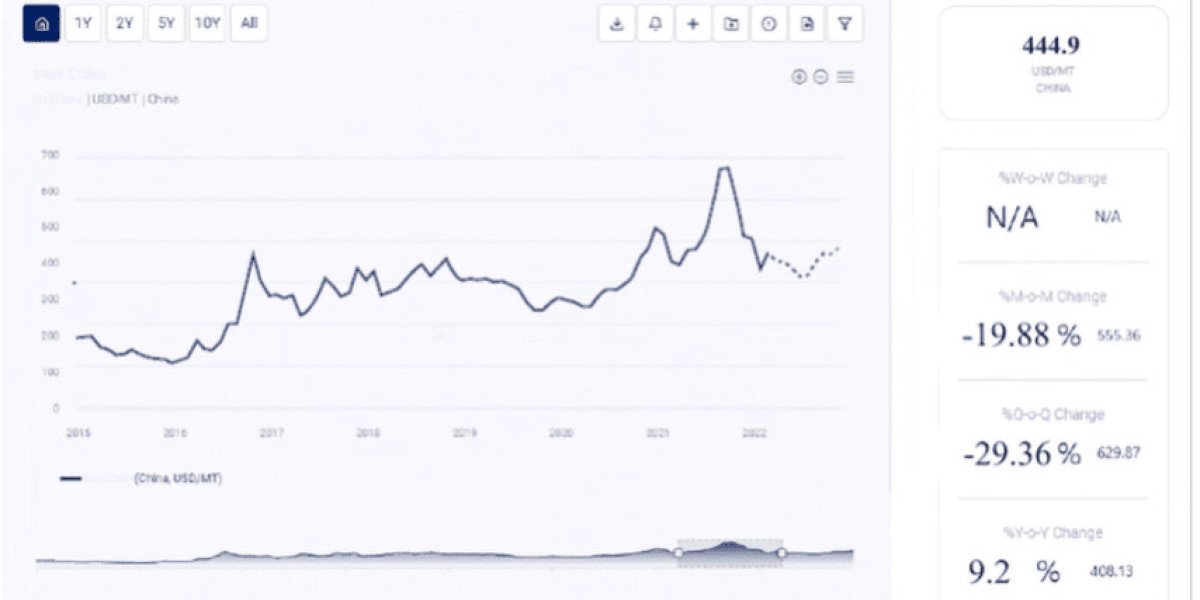

Chromium oxide prices have historically shown significant volatility due to fluctuations in raw material costs, energy prices, and market demand. For example, periods of high demand in the construction and automotive industries can lead to price spikes, while economic downturns can result in decreased demand and lower prices.

Technological Advancements

Advancements in production technologies and processes have helped improve the efficiency and cost-effectiveness of chromium oxide manufacturing. Innovations in chemical synthesis and recycling methods have contributed to more stable prices by reducing dependence on raw materials and energy.

Environmental Compliance

Increasingly stringent environmental regulations have led to higher production costs for chromium oxide. However, these regulations have also driven innovation in cleaner and more efficient production techniques, helping to mitigate some of the cost impacts over time.

Case Studies of Major Chromium Oxide Markets

China

China is one of the largest producers and consumers of chromium oxide. The country’s demand is driven by its vast manufacturing sector, particularly in pigments, ceramics, and refractories. Key factors influencing chromium oxide prices in China include:

- Industrial Growth: Rapid industrialization and urbanization have driven demand for construction materials, coatings, and pigments, impacting chromium oxide prices.

- Environmental Regulations: Stringent environmental policies aimed at reducing emissions and improving sustainability have increased production costs but also promoted the adoption of cleaner technologies.

United States

The United States is a significant consumer of chromium oxide, particularly in the automotive, aerospace, and construction industries. Key factors influencing chromium oxide prices in the U.S. include:

- Market Demand: Demand from the automotive and construction sectors, which use chromium oxide in coatings and refractories, significantly impacts prices.

- Trade Policies: Changes in trade policies, such as tariffs on imported raw materials and finished products, can affect the cost and availability of chromium oxide.

Europe

Europe is another major market for chromium oxide, with significant demand from the automotive, aerospace, and construction industries. Key factors influencing chromium oxide prices in Europe include:

- Sustainability Initiatives: Strong focus on sustainability and environmental regulations in Europe drives demand for eco-friendly products, influencing chromium oxide production processes and costs.

- Industrial Demand: The demand for high-quality coatings, pigments, and refractories in various European industries impacts chromium oxide prices.

The Impact of Climate Change on Chromium Oxide Production Costs

Climate change poses several challenges to chromium oxide production, particularly regarding resource availability and regulatory pressures to reduce carbon emissions. Key impacts include:

- Resource Availability: Changes in climate conditions can affect the availability of raw materials such as chromite ore. Extreme weather events, such as floods and droughts, can disrupt mining operations and supply chains, leading to price volatility.

- Carbon Pricing: Implementing carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, can increase the cost of energy and raw materials, making chromium oxide production more expensive. This incentivizes the adoption of cleaner technologies and alternative energy sources.

- Sustainability Initiatives: The chromium oxide industry is increasingly focusing on sustainability initiatives, such as reducing carbon emissions and promoting responsible sourcing of raw materials. These initiatives can influence production costs and market dynamics.

Future Outlook

Demand Growth

The demand for chromium oxide is expected to remain strong, driven by factors such as industrial growth, urbanization, and the increasing use of pigments and coatings in various applications. Emerging markets, particularly in Asia, are expected to be major drivers of future demand.

Supply Challenges

Supply challenges, including resource availability, environmental regulations, and production costs, will continue to impact chromium oxide prices. Ensuring a stable supply of raw materials and adopting sustainable production practices will be critical for the industry.

Technological Advancements

Technological advancements will play a key role in shaping the future of the chromium oxide industry. Innovations in energy efficiency, recycling, and automation will help producers meet growing demand while addressing environmental and cost challenges. Continued investment in research and development will be essential for maintaining competitiveness and sustainability.

Conclusion

The price of chromium oxide is influenced by a complex interplay of factors, including raw material costs, production processes, market demand, supply dynamics, and environmental regulations. Understanding these factors is essential for stakeholders across the chromium oxide supply chain, from producers to consumers and policymakers. By adopting efficient technologies, implementing sustainable practices, and navigating regulatory landscapes, it is possible to manage production costs effectively and ensure a stable and cost-efficient supply of chromium oxide. As global challenges like climate change continue to evolve, the chromium oxide industry must adapt to maintain the balance between cost, efficiency, and sustainability.