Introduction

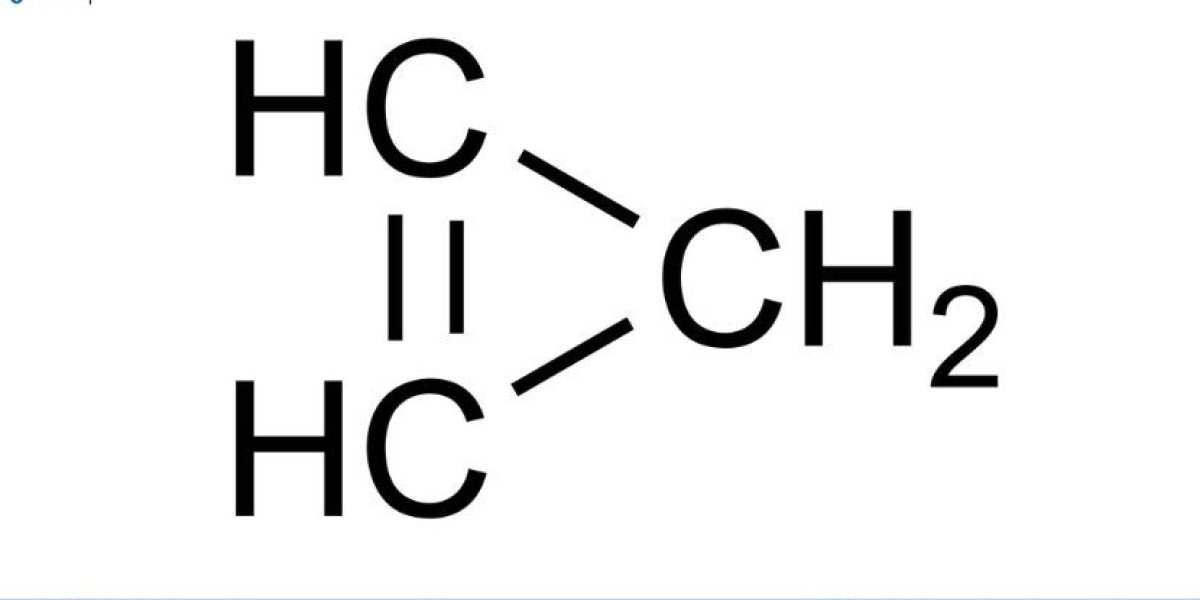

Cyclopropene is an organic compound that plays a significant role in the chemical and pharmaceutical industries. Its unique structure, consisting of a three-membered ring with one double bond, makes it a highly reactive and valuable intermediate in various chemical reactions. The Cyclopropene Manufacturing Plant Project Report outlines the key considerations for setting up a manufacturing plant that produces cyclopropene. This includes a detailed analysis of the production process, raw materials, equipment, market demand, financial feasibility, and regulatory requirements.

Cyclopropene is primarily used in the synthesis of specialty chemicals, agrochemicals, and pharmaceuticals, with its applications extending to the production of polymers and various other chemical products. Its highly reactive nature makes it an essential building block in organic synthesis, and as a result, it has gained considerable attention in the chemical manufacturing sector. This report serves as a guide for investors and entrepreneurs looking to enter the cyclopropene production market.

Market Overview

The demand for cyclopropene is increasing due to its importance in chemical reactions that lead to the production of various commercially valuable compounds. Its use as a synthetic intermediate has driven growth in industries such as:

- Pharmaceuticals: Cyclopropene is used in the synthesis of various pharmaceutical products, including anti-cancer and anti-inflammatory drugs.

- Agrochemicals: It is also used in the production of certain pesticides and herbicides.

- Polymers and Specialty Chemicals: Cyclopropene serves as a monomer for producing polymers with special properties, and as an intermediate in the creation of specialty chemicals.

Key Market Drivers:

- Growing Chemical Manufacturing Sector: The demand for cyclopropene is directly influenced by the growth of the chemical manufacturing sector, particularly in specialty chemicals, agrochemicals, and pharmaceuticals.

- Pharmaceutical Advancements: As new drugs are developed, especially in oncology and other specialized fields, the demand for cyclopropene as a precursor for drug synthesis grows.

- Sustainable Production: There is an increasing push for more sustainable and environmentally friendly chemical production processes. This opens opportunities for cyclopropene producers to develop greener synthesis methods.

Get a Free Sample Report with Table of Contents@

Market Challenges:

- High Production Costs: The production of cyclopropene requires highly specialized equipment and controlled conditions, leading to higher manufacturing costs.

- Supply Chain Volatility: The availability of raw materials can fluctuate, impacting production rates and costs.

Manufacturing Process

The production of cyclopropene typically involves cyclization reactions, which are chemical processes that result in the formation of the three-membered cyclopropene ring structure. Below is a detailed overview of the primary steps in the cyclopropene manufacturing process.

1. Raw Material Preparation:

- The key starting materials for cyclopropene production include simple organic compounds such as ethylene, acetylene, or other precursors that contain carbon-carbon double bonds.

- These compounds are mixed with suitable catalysts to initiate the cyclization process. The quality and purity of raw materials are crucial for the efficiency of the reaction and the quality of the final product.

2. Cyclization Reaction:

- The cyclization process involves the use of high-energy catalysts to promote the formation of the cyclopropene ring. This reaction typically requires precise temperature and pressure conditions to proceed effectively.

- Cyclopropene can be synthesized using a variety of methods, including direct cyclization reactions and catalytic methods, depending on the desired purity and scale of production.

3. Purification:

- After the cyclization reaction, the crude cyclopropene mixture is purified to remove by-products and unreacted starting materials. Common purification methods include distillation, extraction, and chromatography.

- The purified cyclopropene is then subjected to quality control tests to ensure it meets the necessary specifications for further use in chemical synthesis.

4. Storage and Packaging:

- Cyclopropene is highly reactive and needs to be stored in controlled conditions to prevent degradation or undesired reactions. Special storage containers are used to protect the product from moisture and light.

- Packaging is essential to ensure safe transportation to various industries that use cyclopropene in their products. Packaging typically includes air-tight containers or bottles that minimize exposure to environmental factors.

Equipment and Technology

Setting up a Cyclopropene Manufacturing Plant requires advanced equipment and technologies designed for precise chemical reactions and high-level production control. Some of the critical equipment and technology required include:

1. Reactor Vessels:

- Reactor vessels are essential for carrying out the cyclization reaction. These vessels must be capable of withstanding high pressure and temperature conditions while maintaining precise control over reaction parameters.

2. Catalysts and Catalytic Systems:

- Catalysts are crucial for promoting the cyclization of the organic compounds. Specialized catalytic systems are used to optimize reaction yields and minimize the formation of unwanted by-products.

3. Separation and Purification Units:

- After the cyclization reaction, separation and purification units like distillation columns and chromatography systems are necessary to isolate the cyclopropene from impurities and by-products.

4. Storage Tanks:

- Due to cyclopropene’s volatility, it requires specialized storage tanks that are designed to maintain an inert atmosphere and protect the product from environmental contaminants.

5. Control Systems:

- Advanced control systems are needed to monitor the reaction process, regulate temperature, pressure, and catalyst concentration, and ensure optimal production efficiency.

Raw Materials

The production of cyclopropene requires a few key raw materials, which are:

- Ethylene or Acetylene: These organic compounds are used as precursors for the cyclization reaction.

- Catalysts: These include specific metal catalysts or organometallic compounds that facilitate the formation of the cyclopropene ring.

- Solvents: Depending on the method used, certain solvents may be required to help dissolve reactants or aid in the reaction process.

- Inert Gases: Gases like nitrogen or argon are used to maintain an inert atmosphere during the production process and avoid unwanted side reactions.

Site Selection

Choosing the right location for a Cyclopropene Manufacturing Plant is crucial to the success of the operation. The following factors must be considered during the site selection process:

- Proximity to Raw Materials: The plant should be located near the sources of ethylene, acetylene, and other necessary raw materials to reduce transportation costs.

- Infrastructure and Utilities: The site must have access to reliable power, water, and waste management facilities to ensure smooth operations.

- Regulatory Compliance: Compliance with local environmental and safety regulations is critical when selecting a site for chemical manufacturing. The site should be situated in an industrial zone with the necessary infrastructure to handle hazardous materials.

- Logistical Access: Easy access to transportation networks for the delivery of raw materials and shipping of the final product is essential.

Financial Considerations

Establishing a Cyclopropene Manufacturing Plant requires significant capital investment. The financial analysis of the plant includes the following key components:

1. Capital Expenditure (CapEx):

- Initial investments include the cost of acquiring land, constructing the plant, purchasing manufacturing equipment (reactors, purification systems, control systems), and obtaining necessary permits.

2. Operational Expenditure (OpEx):

- Ongoing expenses include raw material costs, labor, energy consumption, and maintenance of machinery. Cyclopropene manufacturing is energy-intensive, so energy costs can make up a significant portion of the operational budget.

3. Revenue Generation:

- Revenue comes from the sale of cyclopropene to industries that use it in the production of chemicals, pharmaceuticals, and agrochemicals. The profitability of the plant will depend on production scale, efficiency, and market demand.

FAQ

1. What is cyclopropene?

Cyclopropene is a highly reactive organic compound that is used in chemical synthesis, particularly in the production of pharmaceuticals, agrochemicals, and polymers.

2. What is the role of cyclopropene in the pharmaceutical industry?

Cyclopropene is used as an intermediate in the synthesis of several pharmaceutical compounds, including drugs for cancer treatment and inflammation.

3. How is cyclopropene produced?

Cyclopropene is produced through a cyclization reaction, typically using ethylene or acetylene as precursors in the presence of catalysts.

4. What are the key raw materials used in cyclopropene production?

The key raw materials for cyclopropene production are ethylene, acetylene, catalysts, solvents, and inert gases.

5. What are the main challenges in cyclopropene production?

Challenges include high production costs, the need for specialized equipment, and maintaining a steady supply of raw materials.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au