It is always important to install gas lines safely and to never put anyone or the lines themselves in danger. That’s the main reason metal gas pipe fittings are frequently chosen in plumbing, HVAC and industrial jobs. Upgrading an old system or working on a fresh one, you’ll need the right fittings for better gas flow and less worry.

Read on to know about the types, preferred materials, common uses and important things to watch out for when dealing with metal gas pipe fittings.

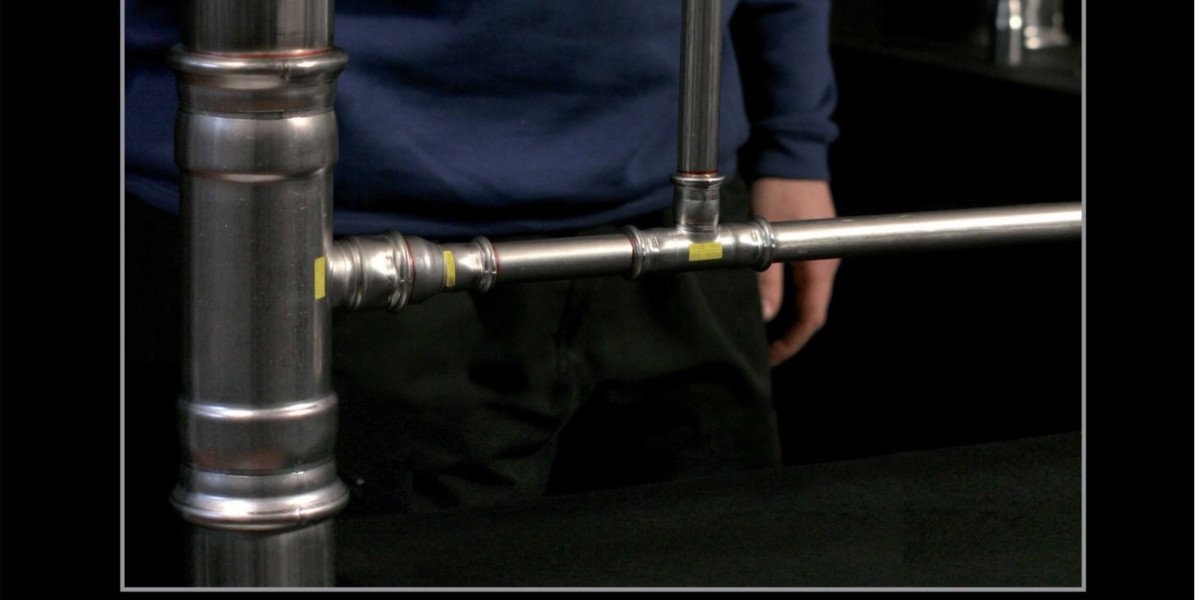

What do metal gas pipe fittings look like?

Metal gas pipe fittings are pieces used to join, change the path of or end the flow of gas. They are necessary to provide confidence that gas pipelines will not leak. Since metal fittings are stronger than plastic gas pipe fittings, high-pressure scenarios are not a problem for them.

Standard types of metal gas pipe fittings

The different fittings are designed for the specific function they perform. Below is a list of the most popular metal gas pipe fittings and their applications:

Elbow - Used to change the direction of the gas flow.

Tees - Used to split the line to two or more directions.

Coupling - Used to connect (join) the two straight pipes.

Reducing coupling - Used to connect a pipe with a different diameter to another pipe.

Cap and plug - Used to seal (end) the pipe.

Union - Used to disconnect to maintenance or modify a system.

Common Materials for Gas Fittings

Various metals have different benefits based on the use case. the most commonly used materials are:

Carbon Steel

Very strong, and able to withstand extreme pressures.

Often used in industrial and commercial applications.

Stainless Steel

Corrosion-free and best suited for applications in the outdoors or wet conditions.

Durable and requires little maintenance.

Brass

Malleable and corrosion resistant.

Easy to install, and ideal for use in residential applications.

Copper

Best used for low-pressure residential gas lines.

Lightweight and easy to work with.

Galvanised Steel

Prior to being abandoned due to corroding with gas, was once the standard material for gas piping.

Typical Uses of Metal Gas Fittings

While there are many uses for metal gas pipe fittings, they are almost always used in:

Residential - Gas lines for heaters, stoves, and outdoor barbecues.

Commercial - Restaurants, retail buildings, multi-residential buildings.

Industrial - Pipelines containing high-pressure gas in factories, and processing plants.

Underground Systems - Metal fittings make excellent underground fittings for long-term use and extreme environments.

How to Choose the Appropriate Fittings

Keep these things in mind when selecting metal gas pipe fittings:

✅ Pressure Ratings – must match required system specifications.

✅ Material Compatibility – ensure fittings are compatible with pipe materials to avoid corrosion.

✅ Environmental Conditions – moisture, temperature, and exposure can influence durability of materials.

✅ Type of Installation – threaded, welded, or press-fit fittings will determine application.

✅ Certifications – ensure fittings used meet AS/NZS gas fitting standards in Australia.

Compliance & Safety Considerations

Dangerous gas leaks may occur when installing non-compliant or substandard fittings. It must always be ensured that:

✅ Fittings used complied with local Australian Gas Standards.

✅ Installation performed by a licensed gas fitter.

✅ Pressure testing must be performed after installation.

Maintenance and Inspection Tips

To ensure longevity and safety of gas pipe fittings, always:

? Inspect fittings for rust, wear, or damage on a regular basis.

? Corroded fittings should be replaced immediately.

? Annual inspections by a licensed gas technician must be scheduled, particularly if installed in a high volume, high consumption or high pressure system.

Where to Purchase Metal Gas Pipe Fittings in Australia

There are some good sources for fittings:

Plumbing wholesalers in Melbourne, Perth or Sydney,

Industrial gas shops

Online shops that supply certified goods (ensure they comply with Australian Standards).

Consider the brands that offer warranties and product certifications for reassurance.

Conclusion

The decision on the selection of suitable metal gas pipe fittings is an important one regarding performance and safety of any gas system. With several metal types, styles and standards available, it’s easier to pick the right type of fitting for compliance. Any home, business or industrial plant may get gas pipe fittings. Purchasing high-quality fitting and using experienced installers helps you cut costs in the future.