Numbered between 1 and 80, they cover sizes from .228" (#1) down to .0135" (#80). Letter Twist Drill Bits cover sizes between the fractional diameters from 1/4" to 1/2". An A drill is .234" and a Z drill is .413" diameter. This is somewhat confusing because the number series becomes smaller from 1/4" as the numbers increase and letter series get larger from 1/4" as the letters increase. Twist drills are also offered in metric sizing, so just about any diameter desired can be obtained.

At the bottom we have a standard length drill which is called a Jobber. Above we had an extra length or aircraft drill. A shorter than jobber length bit is a screw machine drill. It is often hard to tell what size a twist drill is after it spins in a chuck. Drill plates and guides allow you to precisely re-identify such errant renegades.

Normal length drills, such as come in the average assortment, are called jobber length. If a longer drill is needed, a good hardware shop will offer an aircraft or extra-length drill. If a shorter twist drill is desired, it is referred to as a screw-machine drill. Twist drills are offered in solid carbide and carbide-tipped as well. Carbide tungsten machining is the choice for drilling concrete.

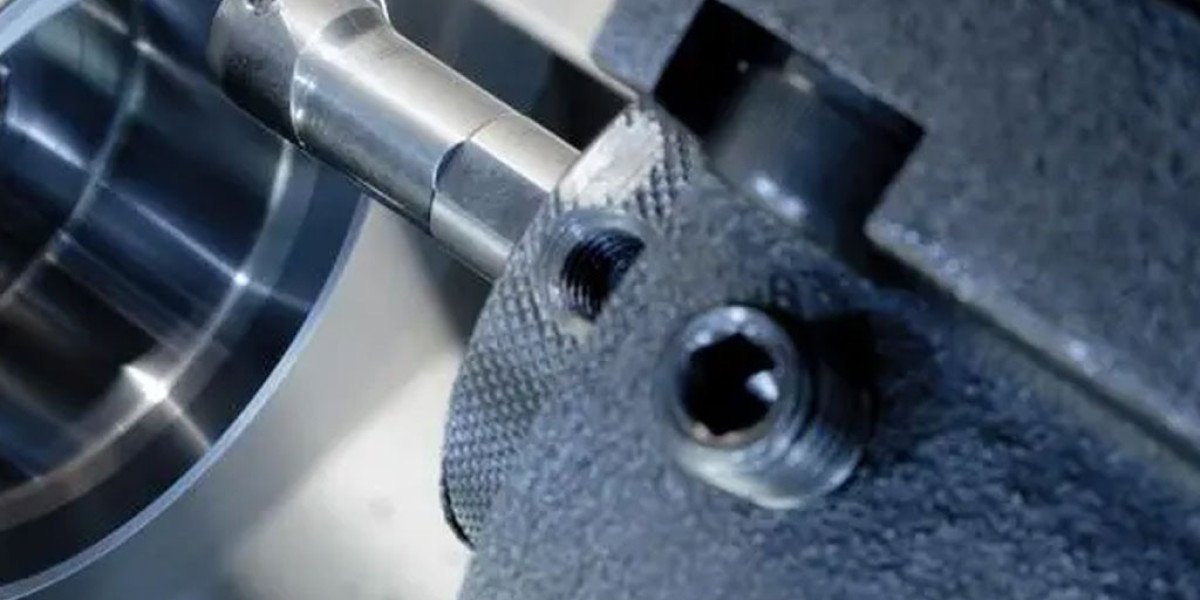

While it is possible to sharpen a twist drill by eye at a bench grinder, a jig or dedicated machine is necessary if out of the box accuracy is to be restored. Here we have two dedicated machines.

Twist drills are difficult for users to sharpen. Great lengths are taken during manufacturing to have the lips at the same vertical height and angle. If the resulting point is not perfectly centered, and each lip does not cut a chip of equal width and thickness, the drill will wander and you will end up with an oversize hole that may not be straight either. While a skilled machinist can sharpen a twist drill by eye on a bench grinder, it will only do non-critical work thereafter! Only a drill sharpening jig or a dedicated machine will restore, new out of the box, accuracy to a dull drill.

Lipping a drill for brass, which will make for easy and safe drilling of brass and copper.

The attack angle of a twist drill is controlled by the rate of twist of the flute. Drills are generally manufactured for cutting steel, which happily works out well for wood as well. This is far too aggressive for nonferrous metals such as brass and copper, which like a 5° negative rake angle. Breakout as the drill exits the material on the far side is particularly troublesome and commonly results in the workpiece spinning on the drill press table or the drill motor spinning in the operator's hands. Either can result in severe injury. This dangerous situation can be almost completely overcome by creating a small flat on the lip that is parallel to the axis of the drill. Called lipping, it turns a unpredictable beast into a gentle pussy cat. What you are doing is effectively changing the rake angle of the drill to 0° instead of 15° positive. The flat does not have to be big, (1/64" or less). The downside of lipping is that the drill will no longer drill steel unless you sharpen the point sufficiently to remove the flat. If you only own one set of drills, that is good reason to keep the lipping flat no larger than necessary.

Plenty of speed is the order of the day when drilling wood. You can use up to 3000 RPM for drills 1/4" and smaller. Speed charts are readily available and it is good to have one on the shop wall. Center punching is a must if you want accurate hole location.

Twist drills are perfect when you want a very accurate diameter hole. Say you want a press fit for a 3/16" (.1875" dia.) steel pin in a cabinet you are building. A #13 drill makes a .185 dia. hole, giving you a .0025 press fit for the pin. When Undercut Machining a very accurate hole it is best to drill 1/64" undersize, and then make the final drilling with a new, or freshly sharpened, drill of the desired diameter. If drilling a large hole this could entail three drillings: drilling 1/4" to expedite the quick sinking of the larger hole you desire, drilling 1/64" undersize and final drilling of the desired size.